The Challenge

India's logistics industry, supporting almost 25% of the overall workforce, saw a boom in third-party operators following the expansion of the road network in the mid-1990s. Unfortunately, the introduction of middlemen operators created a significant challenge in finding ways to track, monitor, and exchange information transparently between all parties (suppliers, distributors, contractors, and buyers). This deficit in trust made it difficult to keep a balanced supply of drivers and led to an increase in contracted truck driver costs, as manufacturers were charged a premium for every hour a driver was on the job.

Companies sought to improve operational efficiencies to reduce costs and increase productivity. While much focus was on speeding up logistics timelines, dealing with the inconsistencies of contracted operators proved difficult. Therefore, many companies focused on operational activities they had control over, such as the locating, packaging, loading, and unloading of containers at their warehouses.

Why LoRaWAN®?

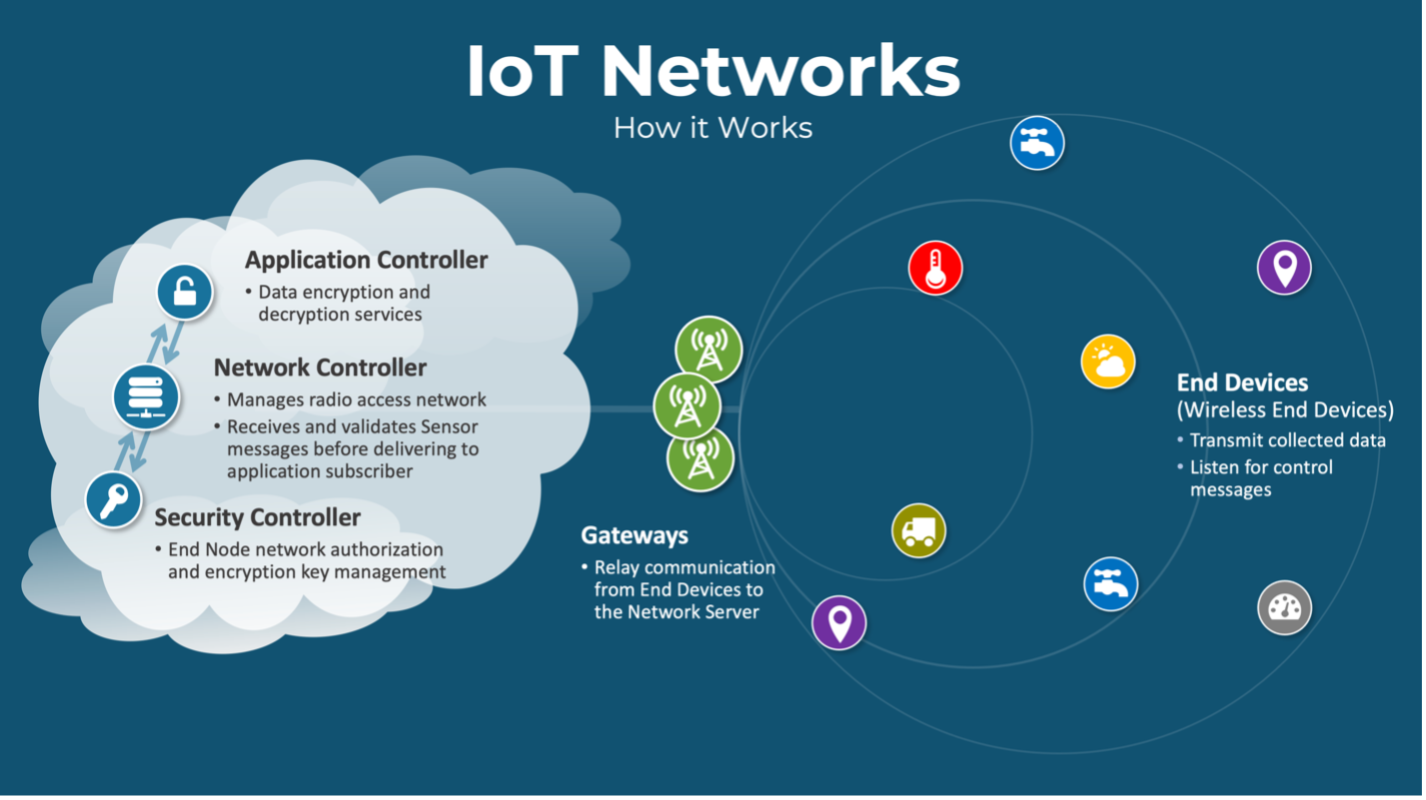

Smart solutions like vehicle tracking and smart inventory management are quickly being adopted in logistics to improve operational efficiencies using the Internet of Things (IoT). However, choosing the right IoT technology presents challenges, especially for warehouse facilities often located in remote areas extending over large plots of land. These locations often lack direct internet access or sufficient LAN connection points, which complicates solutions relying on high-density connectivity. Wi-Fi has limitations with range, and cellular solutions, while offering longer range, are often unavailable in remote areas and suffer from indoor coverage issues due to RF penetration limitations.

LoRaWAN® is an excellent option for solutions that do not require huge amounts of data to be transmitted wirelessly over long-range distances. Key benefits include:

- Minimal Investment: Can provide smart devices with long-range internet access without needing many LAN connections on the grounds.

- Deep Indoor Penetration: Can penetrate hard-to-reach indoor areas, making it suitable for warehouse applications.

LoRaWAN® Implementation: The Solution

A large home appliances company in India needed a smart solution to track truck driver activities at their 8-hectare facility, including entry/exit times and arrival/departure times at specific warehouses. The goal was to monitor time spent on the grounds and predict truck arrival times at each warehouse, displaying this on LED monitors. This would allow the company to prepare containers prior to arrival, reducing truck wait time and overall time on site, creating an opportunity to monetize savings on third-party driver services.

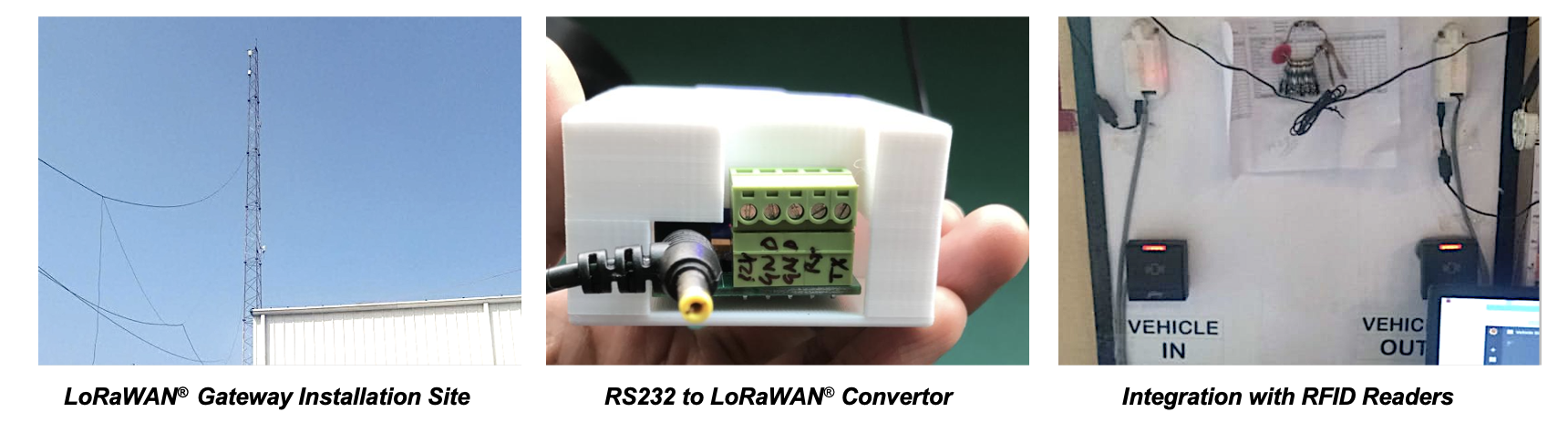

Initially, the company planned an RFID solution (tags given to drivers, readers at pick-up points), but quickly realized the RFID readers required direct LAN access, which was unavailable. They explored alternate back-haul options and identified LoRaWAN as a viable solution.

Touio, in collaboration with ecosystem partners, developed a specialized RS232 to LoRaWAN® converter device. This device connected to the existing RFID reader via the RS232 serial port, allowing it to transmit the RFID data over the LoRaWAN network. An RF survey determined that only one outdoor LoRaWAN® gateway was needed to provide coverage for the entire 8-hectare area, which was installed 40 meters off the ground. After testing confirmed sufficient signal strength, the converters were wired to the RFID readers and verified to properly send data to the central server and LED display monitors.

Benefits and Conclusions

After only one month of implementation, the customer saw significant and immediate benefits:

- 50% Reduction in Truck Driver Time: The average time for a truck to complete all pick-up activities was reduced from 3 days to just 1.5 days.

- Eliminated Idle Time: The smart solution forced truck drivers (averaging 400 visits per day to over 80 pick-up points) to stick to a tight schedule, preventing them from parking idly for hours.

- Estimated Savings: The company was able to save an estimated $3,400 USD per day by reducing the driver's hourly rates and service/fuel charges associated with the extended time on grounds.

This case study demonstrates that focusing on internal problems within a company's control is a strong starting point for digitalization. LoRaWAN proved its ability to support hybrid projects by integrating with existing RFID technology, providing a solution that delivered an immediate return on investment and introduced new monetization opportunities.

LoRaWAN® and LoRa Alliance are marks used under license from the LoRa Alliance.

Explore Smart Logistics Solutions

Touio provides customized solutions for supply chain visibility and connected operations, leveraging technologies like LoRaWAN, Ginjer, and Netsy to drive efficiency and reduce costs.